views

Chemical and fertilizer processing environments generate mist-laden gas streams that demand stable mist separation to protect downstream components and meet emissions requirements. The performance of a mist eliminator in these applications depends heavily on material composition.

From metal mesh to thermoplastic media, each selection influences pressure drop, resistance to corrosion, weight, and long-term operational life. Mist eliminator material selection is not simply a specification—it’s a design requirement rooted in process compatibility and reliability.

Why Material Choice Matters in Mist Elimination

A mist eliminator serves to capture liquid droplets suspended in gas flows, preventing loss of valuable product and safeguarding equipment. Material incompatibility can lead to premature degradation, contamination, and shutdowns.

Chemical processes involving sulfuric acid, nitric acid, ammonia, or chlorine compounds frequently subject separators to corrosive vapors and fine aerosols. In these cases, choosing the wrong material results in short service intervals and uneven removal performance.

Selecting proper material allows industrial mist eliminators to maintain separation integrity under conditions such as:

1. Variable gas velocities

2. Acidic or caustic gas compositions

3. Elevated or fluctuating temperatures

4. High aerosol loading

Mist eliminator suppliers with application-specific knowledge recognize the risks of general-purpose media in such specialized systems.

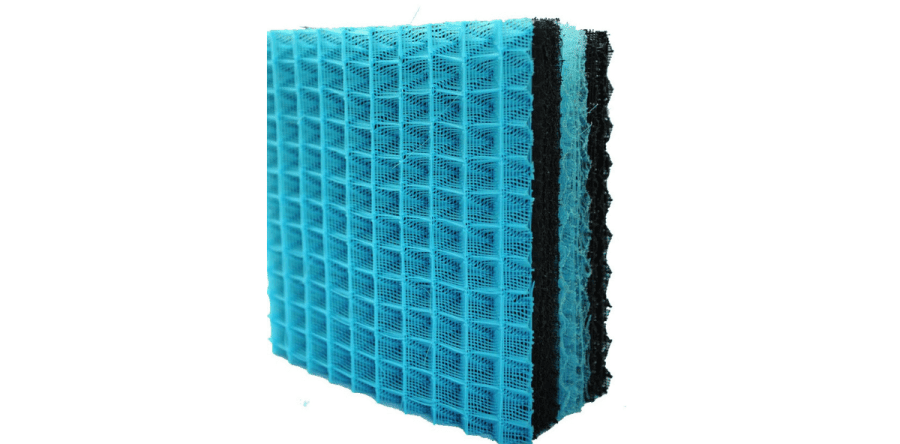

Common Materials Used in Mist Eliminators

Materials used in mist eliminator construction fall into several categories based on resistance profile, structural stability, and operating limits. These materials form the mesh or pad medium, as well as the frame or support structure.

1. Stainless Steel (304, 316, 316L)

Used widely for its corrosion tolerance in acidic environments. Offers strength and structural support but adds significant weight and cost.

2. Polypropylene

A lightweight polymer resistant to many acids and solvents. Suitable for moderate temperatures. Melts or deforms under high thermal loads.

3. PTFE (Polytetrafluoroethylene)

Performs in harsh chemical conditions, including strong acids, oxidizers, and solvents. Higher cost, but superior non-stick properties and thermal resistance.

4. PVC (Polyvinyl Chloride)

Suitable for mildly corrosive gases and low-temperature operations. Common in low-pressure systems.

5. Fiberglass

Widely used in structured packings and specialty applications. Delivers moderate chemical resistance with better thermal properties than some polymers.

6. Polyethylene (PE)

Tolerates a range of low-pH environments. Limited temperature capacity, but good for aqueous mist capture.

Each mist eliminator material carries trade-offs. Material compatibility with gas chemistry, fouling behavior, and cleaning frequency must align with process objectives.

Matching Material to Application: Fertilizer Industry Use Cases

Fertilizer production facilities process substances such as ammonia, urea, nitric acid, and phosphoric acid. Each step introduces vapor streams that may contain corrosive droplets, high solids content, or fine acidic mists. Selecting the wrong moisture eliminator material leads to erosion, plugging, or failure during extended campaigns.

Applications include:

1. Ammonia absorption towers

2. Acid scrubbers

3. Prilling tower off-gas treatment

4. Granulation and drying units

Material recommendations for fertilizer plant systems:

1. PTFE or 316L stainless steel for nitric acid or ammonia absorption units

2. Polypropylene mesh for phosphoric acid with moderate temperature exposure

3. Fiberglass-reinforced frames to reduce weight without sacrificing mechanical support

Mist eliminator suppliers working with fertilizer operations must account for fertilizer-specific fouling characteristics such as particulate agglomeration or acidic condensate backflow.

Matching Material to Application: Chemical Processing Plants

Chemical manufacturing involves a broader range of reactive and high-temperature processes. Industrial mist eliminators in these environments encounter halogen gases, organic vapors, or multi-phase flows. Corrosion, thermal cycling, and particulate impact must all be considered.

Common units include:

1. Chlorine drying towers

2. Sulfuric acid absorbers

3. Hydrochloric acid scrubbers

4. Solvent recovery columns

Material recommendations:

1. PTFE media where resistance to aggressive halogens is required

2. 316L stainless steel in sulfuric acid towers with elevated temperature profiles

3. PVC frames in low-temperature aqueous gas cleaning

4. Polyethylene mesh for light-duty solvent mist capture

Mist eliminator suppliers with process knowledge in chemical manufacturing help refine selection based on chemical structure, dew point, and gas loading patterns.

Factors to Consider When Choosing Material

Material selection is driven by application demands. Mist eliminator performance varies not just by media type, but by its interaction with site-specific gas compositions, cleaning protocols, and fouling rates.

1. Corrosion Resistance

Material must withstand prolonged exposure to process gases without degradation or structural compromise.

2. Temperature Range

Media and frames must tolerate process and ambient thermal cycles without deformation or breakdown.

3. Weight and Structural Load

Heavier materials, such as stainless steel, increase installation complexity. Lightweight alternatives may require reinforcement.

4. Maintenance Requirements

Media that foul quickly or degrade under washdown conditions may increase downtime.

5. Chemical Compatibility

Some gases create aggressive byproducts or condensates. Compatibility with all process phases (vapor and liquid) is required.

6. Process Dynamics

Velocity shifts, pressure drops, or variable flow regimes can affect droplet behavior and loading characteristics.

Mist eliminator suppliers must evaluate all these variables to recommend proper combinations of mesh material, fiber density, and support structure. Suboptimal pairings shorten operating life and elevate operating costs.

Discuss with Kimre for Tailored Solutions

Chemical and fertilizer processing facilities rely on stable mist separation to maintain throughput and compliance. Material compatibility in mist eliminator construction is not optional—it is fundamental to process performance. Stainless steel, PTFE, fiberglass, and polymer mesh types all serve specialized applications, and each requires correct pairing with chemical exposure, temperature, and gas load characteristics.

Facilities seeking consistent separation must work with mist eliminator suppliers who understand gas chemistry and process variability. Matching material to application allows industrial mist eliminators to manage mists, protect downstream equipment, and reduce maintenance frequency.

For engineered moisture eliminator solutions built to withstand corrosive industrial conditions, connect with Kimre, Inc. for application-specific design and consultation.

Comments

0 comment